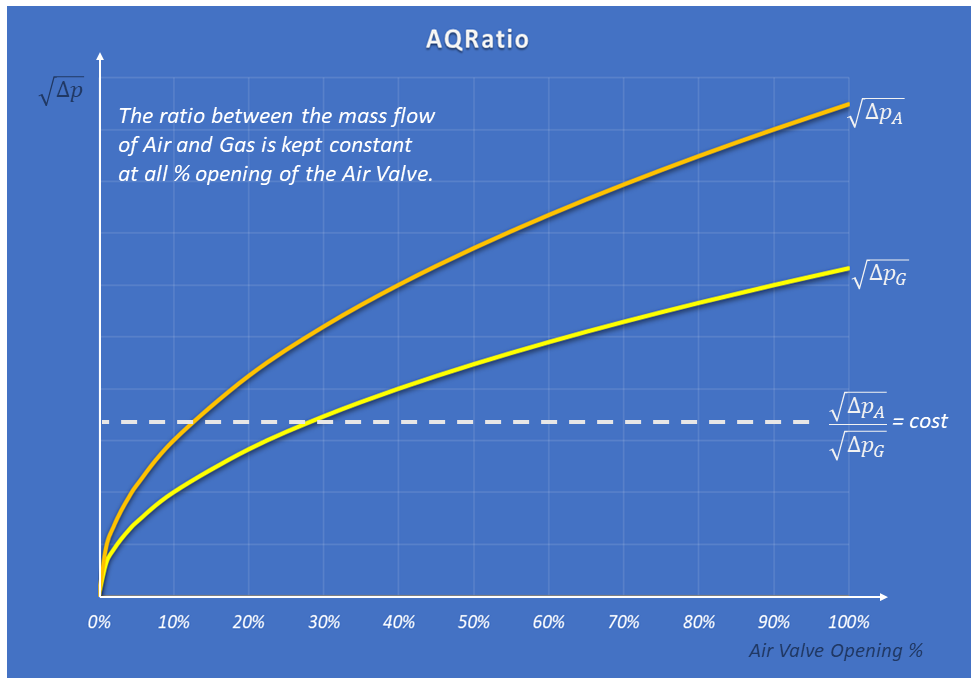

Thanks to AQRatio technology the air/gas ratio is kept constant during the regulation output…

…driven by the temperature profile demand and it is independent of the pressure losses in the air/gas mixture line downstream the regulation skid due to any cause (to fouling in the pipe or in the burners).

FALORNI TECH has developed its combustion systems taking into account the necessity to have simple solutions but flexible and reliable.

Depending on availability, our combustion systems can be fed by NG or LPG. They are entirely designed in compliance with updated engineering standards and they are integrated with the design of channel understructure and superstructure in order to guarantee the expected range of pull thus granting the best temperature stability under pull fluctuations.

Each combustion skid is manufactured as a stand-alone unit made in compliance with EU safety rules in force.

All skids are fully piped-up and wired and are subject to accurate cold tests in our factory before being shipped. This procedure guarantees suitable performances and compliance with quality and operating requirements.

The AQRatio technology is based on the Differential Pressure Governor principle.

A membrane device receives continuously the differential pressure signal taken before and after an orifice, in both air and gas lines. The purpose of the membrane device is to keep a constant preset balancing of the air and gas differential pressure values at the variable flow of combustion air. Being assumed that the differential pressure measured before and after an orifice plate inside one duct with a gaseous fluid in motion is directly proportional to the square of the mass flow of the same fluid, the fact to keep these differential pressures in constant relationship consequently means to keep the flow ratio constant. It is important to highlight that, the measurement of the differential pressure value is not qualitative but quantitative, so there is not reading of flow but only the physical correlation inside the system. Another characteristic of AQRatio technology is the integration of a linear flow control valve to accurately and repeatedly modulate the flow of air at any servomotor angle. The valve controls AIR/GAS ratios up to 25:1 and is suitable for regulating flow rates for modulating or, also, stage-controlled combustion processes.

This type of control valve uses the rotary valve principle in which a control cylinder, with a specially designed opening to determine a linear flow, is installed in the flow body. The rotation of the cylinder around its main axle sets the desired flow rate in the air pipeline. In addition, the maximum flow can be limited in broad ranges by means of a flow-restricting cylinder which allows optimum adaptation to the capacity required, without limiting control quality.

In conclusion, the AQRatio is a modular integration of air and gas flow control technologies aimed to modulate the temperature of the forehearth zones providing:

- Constant Air/Gas ratio at any admittable flow of the line

- Easy adjustment of Air/gas ratio

- Linear airflow adjustment

- Suitable working conditions of air and gas flow control devices

Related arguments:

- FLEX- COND- Flexible Glass Conditioning System

- FLEX- COND and AQRatio: the perfect integration

- Coloring forehearths

- Gathering bays