Inside a melting furnace, there are parts that are more critical than others and that can affect the life of the plant and the quality of the process.

The dog house is one of the most critical parts of a furnace as it is the mean through which the furnace is fed with raw materials and it is the interface between the external environment and the melting tank. Such a particular part holds the entire process of furnace feeding and the way the charging is made is extremely important.

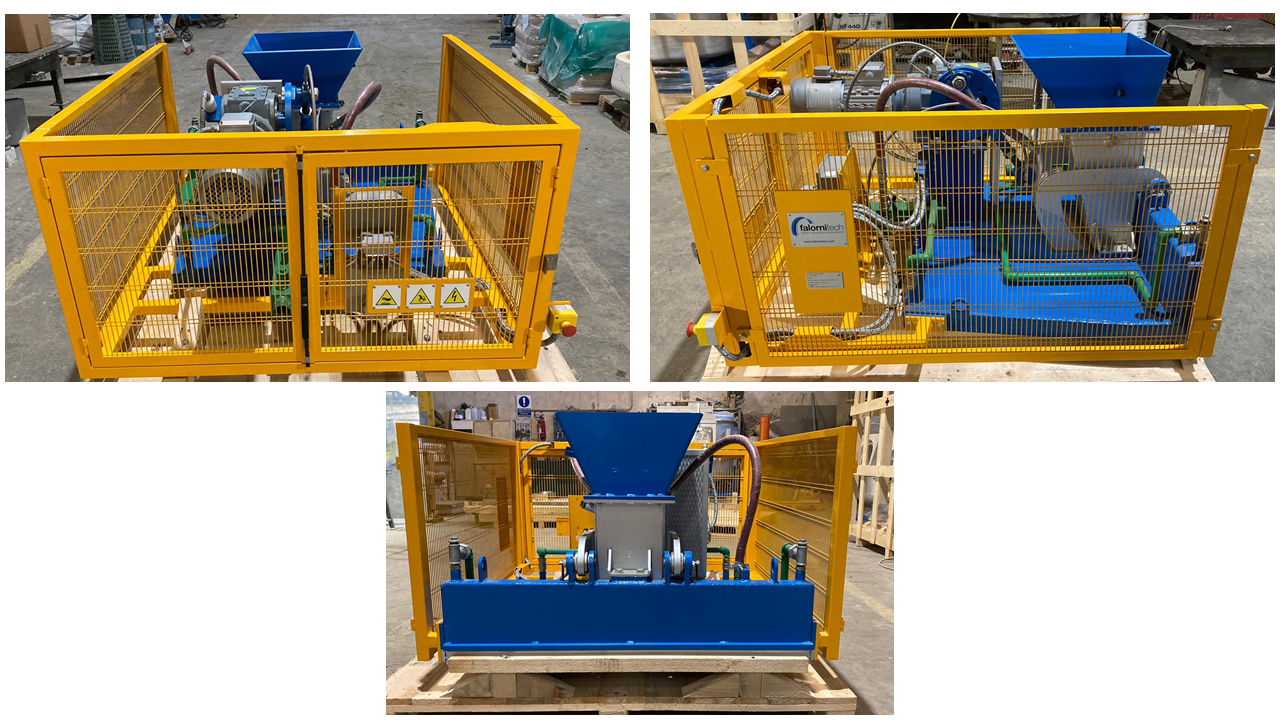

For this reason, Falorni Tech has developed a complete set of batch charging solutions suitable to match with every type of continuous furnace and its melting process. The design, development, and mechanical processing of our batch charging machine is made in our workshop in Empoli.

We supply three families of batch chargers each developed for a specific job.

- Screw type for the continuous furnace of small capacity with flexible pull

- Oscillating tray-type for small and medium capacity furnaces

- Oscillating scoop type for medium up to big capacity furnaces

Each batch charging system is tailored to the furnace and takes into account the glass recipe, the cullet content, the geometry of the dog house as well as the heating system in order to ensure the best performance to the system during all its operating life.